۱۰ دی ۱۴۰۲

پودر میکرونیزه: نگرشی در تولید، محدودیت ها و تجهیزات مورد نیاز

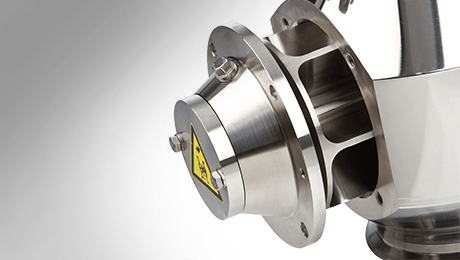

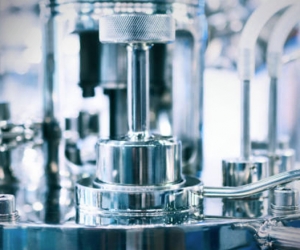

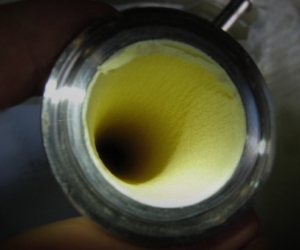

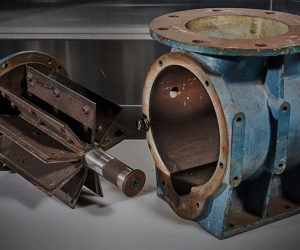

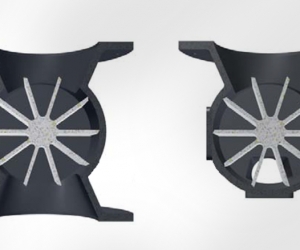

پودرهای میکرونیزه به دلیل خواص منحصر به فرد و کاربردهای گسترده، محبوبیت قابل توجهی در صنایع مختلف به دست آورده اند. هدف این مقاله آشنایی با پودر میکرونیزه، بررسی محدودیتهای آن در طول تولید، و معرفی تجهیزات ضروری و پر کاربرد برای تولید آن با استفاده از روشهایی مانند آسیاب جت میل، آسیاب کلاسیفایرهوایی (ACM) و آسیاب یونیورسال است.

آشنایی با پودر میکرونیزه:

پودر ...

ادامه مطلب