Knowledge Superiority

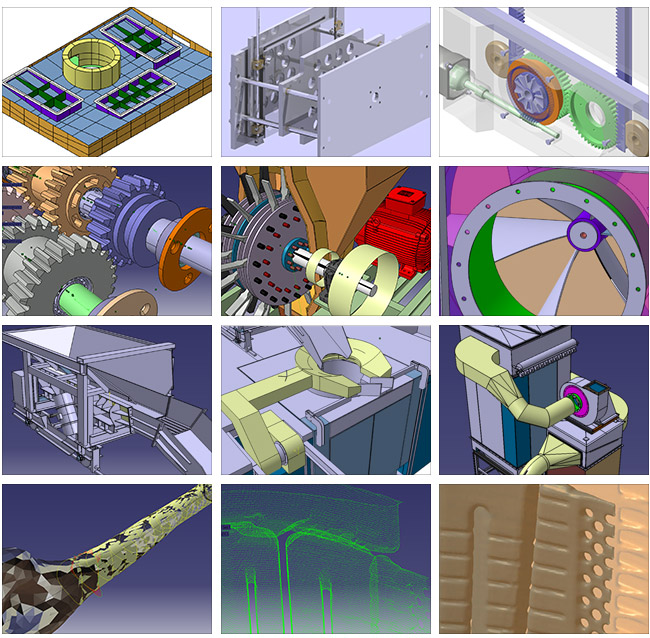

Design Engineering

Design engineers at PAXAA are young and self-motivated. PAXAA engineers endeavor to develop new machines which answer the needs and applications of the industrial customers. Designing at PAXAA is facilitated with the help of latest CAD, CAM & CAE software like CATIA V5, AutoCAD, Mechanical Desktop, ANSYS, MATLAB, FLUENT, Edge CAM, and E-plan. Several software simulations are performed to ensure that a newly developed design is qualified.

CAD

Computer aided Design capabilities cover:

- 2D & 3D modeling of wireframe & solids

- Advanced surface modeling

- Mold & die design

- Fluid piping design

- Air ducting & systems design

- Sheet metal design

- Advance drafting & drawing generation

- Mechanism design & kinematics

- Hydraulic & pneumatic system design & simulation.

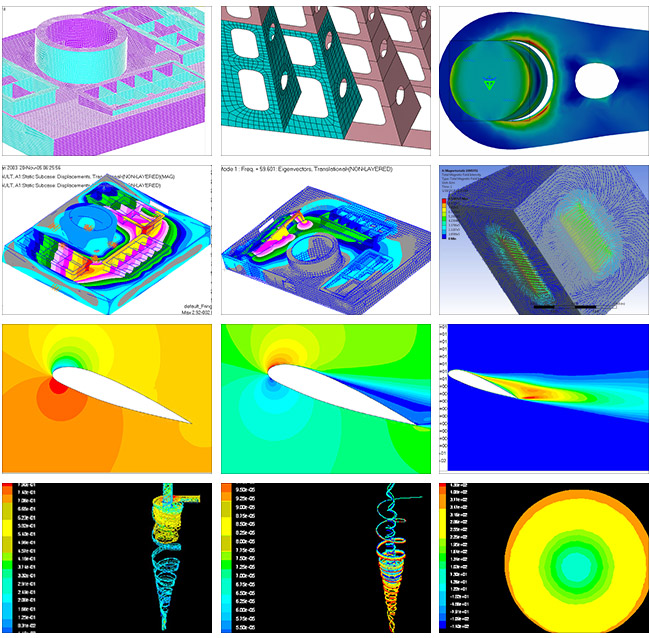

CAE

Computer aided Engineering capabilities covers several fundamental analysis as well as Multi-physic analysis which covers:

- Static & Dynamic structural analysis

- Static & Dynamic analysis of solids, thin shell & assemblies

- Welding & joint analysis

- Natural Frequency & Dynamic response analysis

- Thermal & Heat Transfer analysis

- Magnetic field Analysis

- Internal & external flow newtonian Fluid Flow simulation

- Compressible air flow external aerodynamics

- special software & code development for demanding applications.

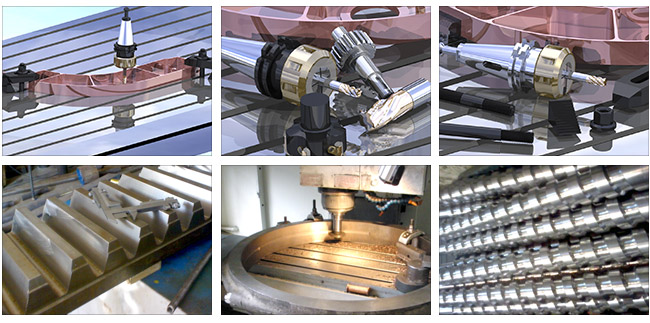

CAM

Computer aided Manufacturing capabilities covers:

- Sheet metal forming

- Casting simulation

- Lath, 3 Axis & 4 Axis CNC machine programming

- Plasma & Laser cutting machine programming

Complete integration in design & Manufacturing in PAXAA brings outstanding capability & flexibility to demanding industrial requirments & provides new opportunities for our customers in competetive world.